ON-LINE

MANUAL

General Information

General information

on pneumatic external vibrators

Introduction

This manual contains information on the two main types of vibrators:

• Rotary vibratord (ball,

roller and turbine vibrators)

• Linear piston vibrators

Historical Background...

Even today in some areas of the globe, just as it was centuries

ago, the hand driven stamper still is very common as a tool to

compact concrete in molds. Similarly, the sledge hammer is the

tool used to support the material flow.

Screens to separate chaff from

corn are known to be the first vibrating application "industrialized",

i.e. the first vibrating element driven by non-human energies

such as water and wind.

Pneumatic driven vibrators were

introduced early this century as linear piston vibrators or pneumatic

hammers. Only years later was the simpler rotary vibrator with

a ball or a roller running circle born. For decades this design

has not been changed. The body was and still is made by many

manufacturers of cast iron and the outside surface is not machined.

At the end of the sixties, the

first experiments with aluminum bodies were conducted. Aluminum

is very simple and clean to machine, with no black casting dust

that covers machines and the hands of the end users. Aluminum

has the strength required but is not too stiff to allow cracks

to form. It can be coated with paint so that modern industrial

designs can be created. For applications in special environments

such as pharmaceutical installations bodies are machined from

stainless steel.

Today, a vast amount of work

is done by vibrators. The main applications are emptying bins

and hoppers, screening materials, and compacting concrete as

well as feeding sand, clay, or any kind of powder or small parts

such as screws. Vibration is also used in the electronics industry

to detect cold joints on printed circuit boards.

In silo and bin applications

air blasters are used to loosen bulky materials. Most of our

agents and representatives sell air blasters as well as vibrators

since the products complement each other.

Classification of vibrators

Vibrators can be classified in general according to the type

of energy they use and the vibration technology :

ENERGY TYPE |

TECHNOLOGY |

Electric

Pneumatic

Hydraulic

|

Rotary/Linear/Magnetic

Rotary / Linear

Rotary |

Basic Information On

Pneumatically Driven Vibrators

What is a vibrator good for?

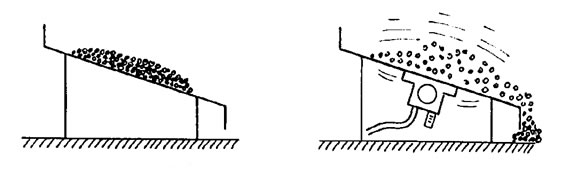

As previously stated, with the

help of vibration any kind of bulky material can be fed, compacted

or separated. In most cases vibration supports the force of gravity.

For instance, bulky material may "hang" and clog in

a hopper because of moisture. Vibration can loosen the material

so the force of gravity can continue to move material through

the hopper.

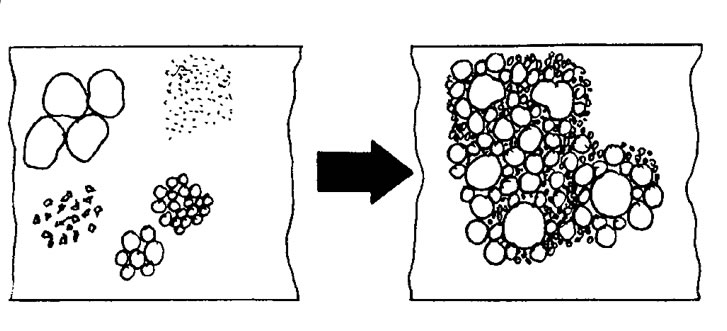

Another application for vibrators

is their use with concrete. Vibrating concrete means to shake

the sand and gravel particles so that they find the most compact

volume possible, with no space available for air. Gravity is

responsible for the first line in compacting but the vibration

supports and improves it very much.

In both the cases vibration

will reduce friction of the material.

Vibrating

and gravity

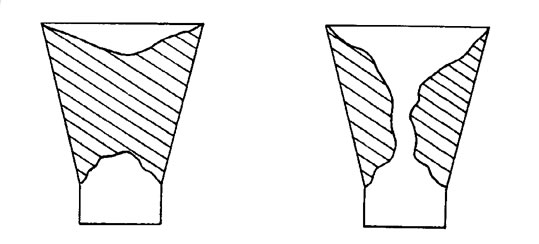

Bridging

and ratholing

Bridging

and ratholing

Compacting

of concrete

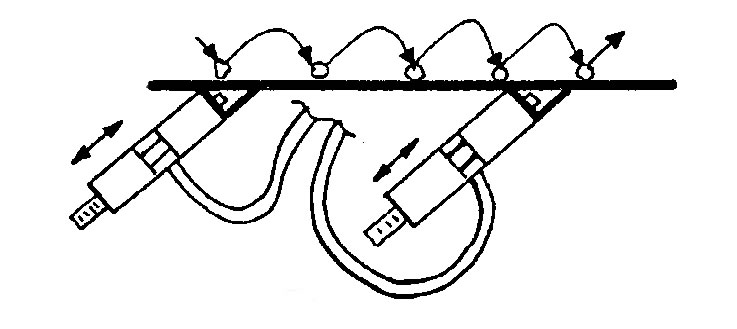

Vibration does not necessarily

suppor the force of gravity. Vibration makes material "jump"

and gravity brings it back to the channel or chute. With the

help of linear vibrators the direction of the material jump can

be defined, and by adjusting the amplitude the length of the

jump can be varied. When the chute slopes downward, rotary vibrators

can be used as well.

Feeding

of materials

Basic information

One thing is most important to know when dealing with any kind

of vibrators: You can certainly calculate natural frequencies

of materials, silos, chutes, etc., but in reality your results

will never be exactly as calculated.

There are tables and even calculation

schemes available to correctly select and position vibrators

with respect to a wide range of force and frequency. However,

the "fine tuning", that is, the optimal adjustment

of the vibrator, is a matter

of practical trials and tests. Field

engineers with some experience may immediately select the best

type of vibrator

as well as the optimal mounting site.

There are some rules of thumb

and tables given under "Selection of the Optimal Vibrator

Type".

To be able to perform optimal

tuning of the vibrator, it is recommended that you put an air

line regulator or a needle valve

in the air pressure line so

the air flow and the air pressure can be controlled.

Finding the natural frequency

of the material that is to be fed, compacted or separated is

the best way

to tune or adjust the vibrator.

The operational frequency range

of pneumatic external vibrators is from 2,000 r.p.m. up to about

20,000 r.p.m.

or about 35 to 350 Hz. The values given in the

technical data sheet were obtained when the vibrator is mounted

to a heavy lab test block, when the vibrator is not actually

working, that is, the amplitude is zero,

but the frequeny speeds

2 to 3 times higher than when mounted to an object.

Often the natural frequency of

the material is out of the operational frequency range of a vibrator.

Thus, a more powerful vibrator has to be used to do the job.

It is not necessary for the vibrator

to run at full power to perform at its best.

It is recommended

that you operate a new vibrator at ? of its maximum power

so that

if power is lost over time

due to abrasion, aging, etc.,

the frequency can be increased to compensate properly.

NOTE:

The pneumatic rotary and

linear vibrator must not be operated with more than 100 PSI (7 BARS) of operating pressure.

NEXT TO VIBRATOR SELECTION